Sinowa is rock wool sandwich panel production line manufacturer from china, dedicated to the research and development of high-end and high-efficiency, Sinowa is comprehensively taking the leading position in terms of efficiency, automation control level, HMI, environment protection and energy consumption, with subversive designs made in some critical technological fields to procure exceptional cost performance and customer-friendly experience for the entire rock wool sandwich panel production line. The adoption of system integration technology and bus control technology accomplishes the full automatization of integrated and coordinated control of the entire rock wool sandwich panel production line with accessible remote interactive communication. Ranking the first-class level in the world, it is currently the rock wool sandwich panel production line in the market taking a comprehensive lead in high performance.

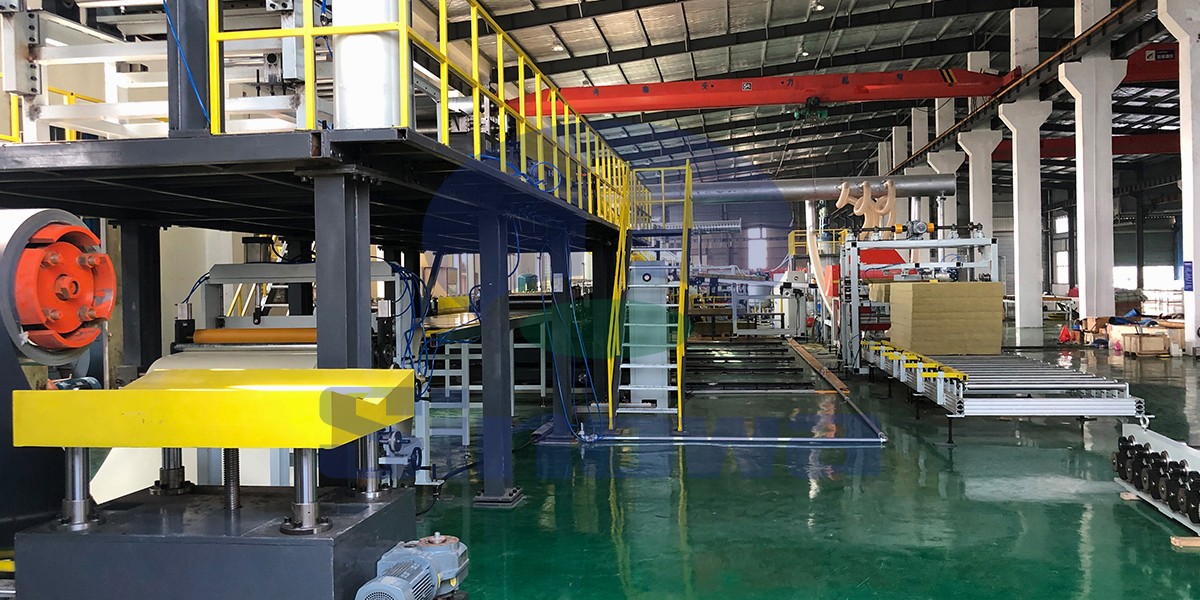

In the contemporary construction and industrial insulation sectors, rock wool sandwich panels have emerged as a pivotal material, celebrated for their exceptional fire resistance, thermal insulation, acoustic performance, and sustainability. Behind these high-performance panels lies a sophisticated and integrated manufacturing system—the rock wool sandwich panel production line. This continuous and automated production line combines mechanical engineering, electrical control, hydraulic systems, and composite material technology to transform raw materials into standardized or customized panels that meet the diverse needs of commercial, industrial, and public construction projects. As global demands for energy-efficient and fire-safe buildings continue to rise, the rock wool sandwich panel production line has evolved from a simple assembly system into a high-tech manufacturing solution, driving innovations in the construction material industry and supporting the transition to greener building practices.

1. Core Components of the Rock Wool Sandwich Panel Production Line

A standard rock wool sandwich panel production line is a modular system composed of multiple functional units, each designed to perform specific tasks in the manufacturing process. From raw material feeding to final product packaging, each component operates in synergy to ensure continuity, precision, and consistency. The key components can be categorized into six main modules: unwinding and forming module for surface panels, rock wool core processing module, bonding and composite module, heating and curing module, cutting and finishing module, and stacking and packaging module. Each module integrates advanced technologies such as frequency conversion control, servo drive, and computerized automation to achieve high-efficiency production.

1.1 Unwinding and Forming Module for Surface Panels

The surface panels of rock wool sandwich panels are typically made of color-coated steel sheets, galvanized steel sheets, or aluminum sheets, which provide structural strength and weather resistance. The unwinding and forming module is responsible for feeding, leveling, and shaping these sheet materials. The core equipment in this module includes hydraulic uncoilers, leveling machines, ribbing devices, and roll forming machines.

Hydraulic uncoilers are designed to hold large rolls of sheet metal (with diameters usually ranging from 800mm to 1200mm) and feed them into the subsequent process at a stable speed. Equipped with tension control systems, they prevent the sheet metal from wrinkling or stretching during unwinding, ensuring the flatness of the surface panels. Leveling machines then correct any deformation or unevenness in the sheet metal caused by rolling and storage, further enhancing the flatness of the base material. Ribbing devices create reinforcing ribs on the sheet metal surface, which improve the mechanical strength and load-bearing capacity of the final panels—critical for applications such as roof panels and exterior wall panels. Finally, roll forming machines use a series of precision rollers to shape the sheet metal into the desired profile (e.g., corrugated, tongue-and-groove, or flat panels) through gradual bending. The roll forming process is controlled by servo motors, which ensure that the profile dimensions meet strict tolerances, typically within ±0.5mm.

1.2 Rock Wool Core Processing Module

The rock wool core is the soul of the sandwich panel, contributing to its thermal insulation, fire resistance, and acoustic performance. The rock wool core processing module is tasked with cutting, shaping, and preparing the rock wool slabs for composite bonding. This module includes rock wool slab feeding devices, slitting machines, edge milling equipment, and fiber direction adjustment systems.

Rock wool slabs (usually with standard sizes of 2400mm×1200mm or 1800mm×1200mm and thicknesses up to 105mm) are first fed into slitting machines, which cut them into strips of the required thickness (ranging from 50mm to 250mm, depending on the final panel specification). The slitting process uses high-precision blades and gap control systems to ensure that the slit rock wool strips have uniform thickness, with a tolerance of ±2mm. Edge milling equipment then trims the edges of the rock wool strips to ensure they fit perfectly with the surface panels and avoid gaps in the composite structure. A key innovation in this module is the fiber direction adjustment system, which turns the rock wool strips to make the fiber direction vertical. This vertical fiber arrangement significantly improves the compressive strength and shear resistance of the final panel, making it more suitable for load-bearing applications.

1.3 Bonding and Composite Module

The bonding and composite module is critical for ensuring the structural integrity and performance of the rock wool sandwich panel. This module integrates glue spraying systems, rock wool positioning devices, and double-belt composite conveyors. The core task is to firmly bond the upper surface panel, rock wool core, and lower surface panel into a single composite structure.

Glue spraying systems use high-pressure nozzles to apply adhesive evenly on the inner surfaces of the upper and lower surface panels. The type of adhesive typically used is a two-component polyurethane (PU) adhesive, which offers strong bonding strength, good weather resistance, and compatibility with both metal and rock wool materials. The glue spraying amount is precisely controlled by computer systems, usually ranging from 180g to 250g per square meter, to ensure sufficient bonding without excessive glue waste. Rock wool positioning devices then place the processed rock wool strips onto the lower surface panel with high precision, ensuring that the core is centered and aligned with the edges of the surface panels. The composite structure (upper panel + adhesive + rock wool core + adhesive + lower panel) is then fed into the double-belt composite conveyor, which applies uniform pressure (typically 0.3 to 0.5 MPa) to ensure tight bonding between the layers. Some advanced production lines also include side-sealing systems, which use PU foam to seal the edges of the composite panel, enhancing its thermal insulation and water resistance by preventing air and moisture infiltration.

1.4 Heating and Curing Module

After composite bonding, the adhesive needs to be cured to achieve its full bonding strength. The heating and curing module is designed to provide a controlled temperature environment for the composite panels, accelerating the curing process while ensuring uniform curing. This module primarily consists of a double-belt heating conveyor, which integrates heating elements (electric, gas, or thermal oil heating) and temperature control systems.

The composite panels pass through the double-belt heating conveyor, where the temperature is maintained between 80°C and 120°C. The heating time is adjusted according to the production speed and adhesive type, usually ranging from 3 to 5 minutes. The double-belt design ensures that the panels are heated evenly from both sides, preventing warping or deformation caused by uneven temperature distribution. Temperature sensors placed at multiple points along the conveyor continuously monitor the heating environment, and the computer control system adjusts the heating power in real time to maintain stable temperature conditions. This precise temperature control is critical for ensuring the curing quality of the adhesive—insufficient curing will reduce the bonding strength, while overheating may degrade the rock wool core or the surface panel coating.

1.5 Cutting and Finishing Module

Once the composite panels are fully cured, they are fed into the cutting and finishing module to be cut into the required length and undergo edge trimming. This module includes automatic tracking band saws, edge trimming machines, and dust collection systems.

Automatic tracking band saws use servo motors and position sensors to cut the continuous composite panel into individual panels of the desired length (ranging from 1.8m to 12m, depending on customer requirements). The saw blades are designed to cut through both metal surface panels and rock wool core with high precision, ensuring that the cut edges are flat and free of burrs. The automatic tracking function ensures that the cutting direction is perpendicular to the panel length, maintaining the dimensional accuracy of the final product (length tolerance ±1mm). Edge trimming machines further refine the edges of the cut panels, removing any excess adhesive or rock wool fibers and ensuring that the panel edges are smooth and uniform. Dust collection systems are integrated into this module to capture the rock wool dust and metal particles generated during cutting, improving the working environment and complying with environmental protection requirements.

1.6 Stacking and Packaging Module

The final module in the production line is responsible for stacking the finished panels and packaging them for transportation and storage. This module includes automatic stackers, conveying rollers, and wrapping machines.

Automatic stackers use robotic arms or mechanical lifting devices to stack the finished panels neatly according to preset quantities (usually 5 to 10 panels per stack). The stacking process is controlled by computer systems, which ensure that the panels are aligned correctly and avoid damage to the surface coating. Conveying rollers then transport the stacked panels to the wrapping machine, which uses stretch film or waterproof paper to wrap the stacks tightly. This packaging not only protects the panels from scratches, moisture, and dust during transportation but also facilitates handling and storage. Some advanced production lines also include labeling systems that print product specifications (e.g., thickness, length, core density) on the packaging, improving logistics management efficiency.

2. Working Principles and Operational Characteristics

2.1 Core Working Principles

The rock wool sandwich panel production line operates on the principle of continuous and automated composite manufacturing. The entire process can be summarized as follows: raw material preparation (uncoiling of surface panels and feeding of rock wool slabs) → processing of surface panels (leveling, ribbing, roll forming) → processing of rock wool core (slitting, edge milling, fiber direction adjustment) → bonding (adhesive spraying, core positioning) → composite pressing → heating and curing → precision cutting → stacking and packaging. Each step is controlled by a central computer system, which coordinates the speed, pressure, temperature, and positioning of each component to ensure the continuity and consistency of the production process.

A key feature of the production line is its closed-loop control system. Sensors placed at various points along the line (e.g., temperature sensors in the heating module, position sensors in the cutting module, tension sensors in the unwinding module) continuously collect operational data and feed it back to the central control system. The system then adjusts the operational parameters in real time to correct any deviations, ensuring that the final product meets the required quality standards. For example, if the tension sensor detects that the surface panel is under excessive tension, the control system will reduce the speed of the uncoiler to adjust the tension; if the temperature sensor detects a drop in the heating conveyor, the system will increase the heating power to maintain the set temperature.

2.2 Operational Characteristics

The modern rock wool sandwich panel production line exhibits four key operational characteristics: high automation, high efficiency, high precision, and flexibility.

High automation is achieved through the integration of computerized control systems, servo drives, and hydraulic systems. The entire production process, from raw material feeding to final packaging, can be completed with minimal human intervention. A typical production line requires only 5 to 8 operators to monitor the operational status, adjust parameters, and handle occasional maintenance tasks—significantly reducing labor costs and the risk of human error. Some advanced lines even feature remote monitoring and control functions, allowing operators to monitor production data and adjust parameters from a central control room.

High efficiency is reflected in the production speed and capacity of the line. The production speed typically ranges from 3 to 8 meters per minute, which can be adjusted according to the thickness and type of the panel. Based on 250 working days per year and 10 working hours per day, a single production line can achieve an annual capacity of 800,000 to 1,000,000 square meters—meeting the large-scale demand of construction projects. The continuous production design eliminates the need for machine stops between batches, further improving production efficiency.

High precision is ensured by advanced mechanical design and precise control systems. The roll forming process achieves profile dimensional accuracy within ±0.5mm, the cutting process achieves length accuracy within ±1mm, and the adhesive spraying system achieves uniform glue application with a deviation of less than 10g per square meter. This high precision ensures that the finished panels have consistent dimensions and performance, facilitating on-site installation and improving the quality of the final building structure.

Flexibility is another important characteristic of modern production lines. The modular design allows for easy adjustment of production parameters to produce panels of different specifications. For example, by adjusting the slitting machine, panels with core thicknesses ranging from 50mm to 250mm can be produced; by changing the roll forming rollers, different surface profiles (corrugated, flat, tongue-and-groove) can be achieved; by adjusting the cutting length, panels of different lengths can be customized to meet the specific requirements of different projects. This flexibility enables manufacturers to respond quickly to market demands and expand their product range without significant modifications to the production line.

3. Application-Driven Optimizations of the Production Line

The performance requirements of rock wool sandwich panels vary significantly across different application scenarios, which has driven continuous optimizations of the production line. By adjusting components and processes, manufacturers can tailor the production line to produce panels that meet the specific needs of different sectors, such as industrial buildings, commercial buildings, public facilities, and industrial equipment insulation.

Optimization for Industrial Building Applications

Industrial buildings (e.g., factories, warehouses, logistics centers) require rock wool sandwich panels with high load-bearing capacity, weather resistance, and fire resistance. To meet these requirements, the production line is optimized in several ways: first, the roll forming module is equipped with reinforced rollers to create surface panels with deeper ribs, enhancing the load-bearing capacity of the panels; second, the bonding module uses high-strength PU adhesive with improved weather resistance, ensuring that the panels can withstand harsh industrial environments (e.g., high humidity, temperature fluctuations); third, the side-sealing system is enhanced to provide better water resistance, preventing moisture infiltration which can degrade the rock wool core. Additionally, the production line can be adjusted to produce larger panel sizes (e.g., 12m in length) to reduce the number of joints during installation, improving the efficiency of industrial building construction.Optimization for Commercial and Public Building Applications

Commercial and public buildings (e.g., shopping malls, gymnasiums, conference centers) have higher requirements for acoustic performance, aesthetics, and energy efficiency. To address these needs, the production line is optimized to produce panels with improved acoustic insulation and decorative properties. For example, the rock wool core processing module can be adjusted to use rock wool with higher density (120 to 140 kg/m³), which enhances the acoustic absorption capacity of the panels (sound insulation effect can reach RW = 29-30 dB). The surface panel forming module can produce panels with various decorative profiles and colors, eliminating the need for additional decoration after installation. Additionally, the heating and curing module is optimized to ensure uniform adhesive curing, which maintains the thermal insulation performance of the panels (thermal conductivity around 0.035 W/m·K), helping to reduce the energy consumption of commercial and public buildings.Optimization for Industrial Equipment Insulation Applications

Rock wool sandwich panels are also widely used for insulation in industrial equipment such as drying tunnels, industrial furnaces, and heat treatment systems. These applications require panels with high-temperature resistance (up to 650°C) and excellent thermal insulation. To meet these requirements, the production line is optimized to use high-temperature-resistant rock wool core material and surface panels (e.g., stainless steel sheets). The bonding module uses high-temperature-resistant adhesive that can maintain bonding strength at elevated temperatures. The heating and curing module is adjusted to use lower heating temperatures and longer curing times to avoid damaging the high-temperature-resistant materials. Additionally, the cutting module is equipped with specialized blades that can cut through stainless steel and high-density rock wool with high precision.

4. Environmental Considerations and Sustainable Development

As the global construction industry shifts toward sustainability and carbon neutrality, the rock wool sandwich panel production line is also evolving to reduce its environmental impact and enhance the sustainability of the final product. Rock wool itself is a sustainable material, as it is made from natural basalt rock (a renewable resource) and can be recycled. However, the production process of rock wool sandwich panels traditionally consumes significant energy, which has prompted manufacturers to adopt energy-saving technologies and green manufacturing practices.

One key area of optimization is energy efficiency. Modern production lines use energy-saving motors and frequency conversion control systems, which reduce energy consumption by adjusting the motor speed according to production demand. For example, when the production speed is reduced, the frequency converter automatically reduces the motor power, resulting in energy savings of up to 30% compared to traditional fixed-speed motors. The heating module also adopts efficient heating elements (e.g., thermal oil heating) and heat recovery systems, which capture and reuse waste heat generated during the heating process, further reducing energy consumption.

Another important environmental consideration is the reduction of waste and emissions. The precision cutting and slitting systems minimize the generation of rock wool dust and metal waste. Dust collection systems with high-efficiency filters capture over 99% of the rock wool dust, preventing air pollution and protecting the health of operators. Additionally, manufacturers are adopting water-based adhesives and low-VOC (volatile organic compound) materials, reducing the emission of harmful chemicals into the environment. The waste rock wool and metal generated during production are collected and recycled, contributing to a circular economy.

Furthermore, the production line is designed to support the production of more sustainable panels. For example, by optimizing the rock wool core density and adhesive application, manufacturers can produce panels with higher thermal insulation performance, which help reduce the energy consumption of buildings. Some production lines also support the use of recycled metal sheets as surface panels, further reducing the carbon footprint of the final product.

5. Future Trends of the Rock Wool Sandwich Panel Production Line

Looking ahead, the rock wool sandwich panel production line is poised to undergo further technological innovations, driven by the growing demands for smarter manufacturing, higher performance materials, and stricter environmental regulations. Four key trends are likely to shape the future of this production system: intelligence, integration of new materials, customization, and global standardization.

Intelligence and Digitalization

The integration of artificial intelligence (AI), machine learning, and Internet of Things (IoT) technologies will transform the rock wool sandwich panel production line into a smart manufacturing system. AI-powered quality control systems will use computer vision to detect defects (e.g., uneven adhesive application, core misalignment, surface scratches) in real time, reducing the rate of defective products. Machine learning algorithms will analyze production data (e.g., speed, temperature, pressure) to optimize operational parameters and predict maintenance needs, minimizing downtime. IoT sensors will connect all components of the production line to a cloud-based platform, enabling real-time monitoring, remote control, and data-driven decision-making. This intelligence will not only improve production efficiency and product quality but also reduce operational costs and environmental impact.Integration of New Materials and Technologies

The future production line will integrate new materials and technologies to enhance the performance of rock wool sandwich panels. For example, the use of nanocoatings on surface panels will improve their corrosion resistance and durability, extending the service life of the panels. The development of bio-based adhesives will further reduce the environmental impact of the production process. Additionally, the integration of 3D scanning and printing technologies will enable more precise shaping of the rock wool core and surface panels, opening up new design possibilities for complex profiles and customized shapes.High Degree of Customization

As construction projects become more diverse and complex, the demand for customized rock wool sandwich panels will continue to grow. Future production lines will be designed to support high-degree customization with minimal setup time. Modular components will allow for quick changes in panel thickness, length, profile, and core material. Advanced computer-aided design (CAD) systems will enable manufacturers to create custom panel designs based on customer requirements, and the production line will automatically adjust parameters to produce the customized panels. This flexibility will enable manufacturers to serve niche markets and meet the unique needs of individual projects.Global Standardization and Environmental Compliance

With the global push toward carbon neutrality and sustainable development, future production lines will need to comply with increasingly strict environmental regulations and global standards. Manufacturers will adopt unified production standards to ensure that their products meet the requirements of different regions (e.g., European green building standards, North American energy efficiency standards). The production line will be designed to minimize carbon emissions, energy consumption, and waste generation, aligning with the goals of the circular economy. Additionally, the use of renewable energy (e.g., solar power, wind power) to power the production line will become more common, further reducing its environmental footprint.

6. Conclusion

The rock wool sandwich panel production line is a critical component of the modern construction material industry, enabling the efficient and high-quality production of panels that meet the growing demands for fire safety, energy efficiency, and sustainability. Through the integration of advanced technologies such as automation, precision control, and closed-loop monitoring, this production system has evolved from a simple assembly line into a sophisticated manufacturing solution, offering high efficiency, precision, and flexibility.

The core components of the production line work in synergy to transform raw materials into finished panels, with each module optimized to perform specific tasks in the continuous manufacturing process. Application-driven optimizations ensure that the production line can tailor panels to meet the unique requirements of different sectors, from industrial buildings to commercial facilities and industrial equipment insulation. Environmental considerations have become a key driver of innovation, with manufacturers adopting energy-saving technologies, waste reduction measures, and sustainable materials to reduce the environmental impact of the production process.

Looking to the future, the rock wool sandwich panel production line will continue to evolve toward intelligence, integration of new materials, customization, and global standardization. These trends will not only improve the efficiency and performance of the production system but also support the global transition to greener and more sustainable building practices. As the construction industry continues to prioritize safety, energy efficiency, and sustainability, the rock wool sandwich panel production line will remain a key enabler of these goals, driving innovations in the construction material industry and shaping the future of building design and construction.

《Rock Wool Sandwich Panel Production Line》Release Date: 2023/11/17

URL: https://www.sinowamachine.cn/en/tag/rock-wool-sandwich-panel-production-line.html

- PU Sandwich Panel Making Machine

- Rockwool Sandwich Panel Production Line

- PU Sandwich Panel Machine

- PU Sandwich Panel Production Line

- Mineral Wool Sandwich Panel Machine

- PUF Panel Machine

- Rock Wool Sandwich Panel Line

- Sandwich Panel Machines

- Sandwich Panel Lines

- Rockwool Sandwich Panel Machine

- Rockwool Sandwich Panel Line

- PU Sandwich Panel Line

- PU Panel Machine

- Foam Forming Machine

- Continuous Sandwich Panel Line

- Continuous PU Sandwich Panel Line

- PIR Sandwich Panel Line

- Polyurethane Sandwich Panel Line

- Automatic PU Sandwich Panel Production Line

- PU Foam Sandwich Panel Production Line