Sinowa is rockwool sandwich panel machine manufacturer from china, dedicated to the research and development of high-end and high-efficiency, Sinowa is comprehensively taking the leading position in terms of efficiency, automation control level, HMI, environment protection and energy consumption, with subversive designs made in some critical technological fields to procure exceptional cost performance and customer-friendly experience for the entire rockwool sandwich panel machine. The adoption of system integration technology and bus control technology accomplishes the full automatization of integrated and coordinated control of the entire rockwool sandwich panel machine with accessible remote interactive communication. Ranking the first-class level in the world, it is currently the rockwool sandwich panel machine in the market taking a comprehensive lead in high performance.

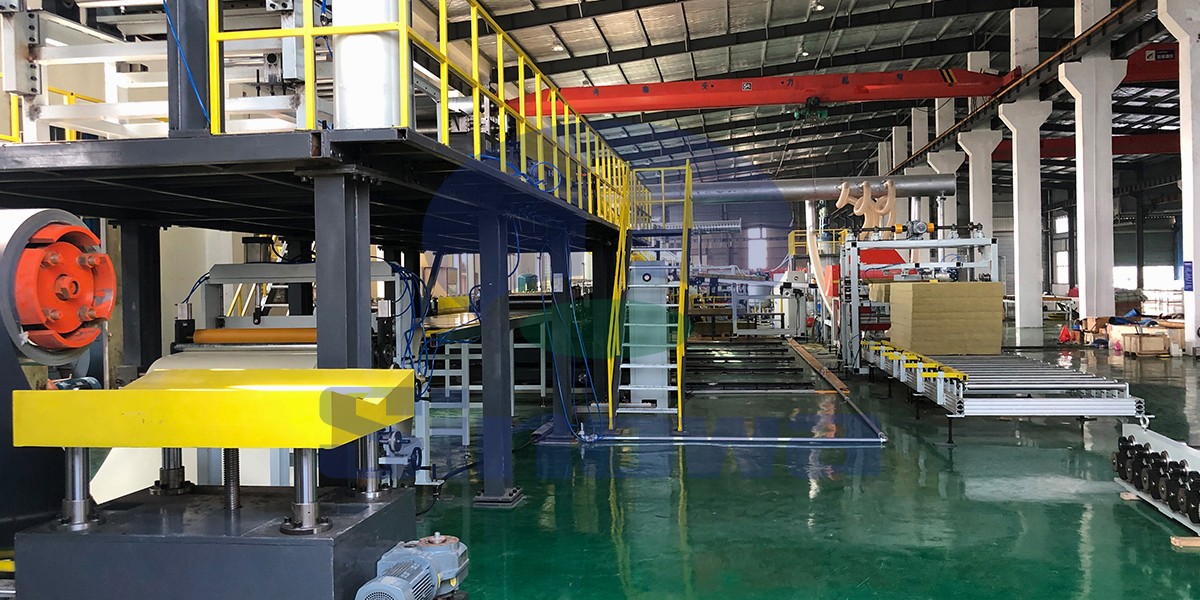

In the modern construction and industrial material manufacturing industry, rockwool sandwich panels have emerged as a pivotal material due to their excellent thermal insulation, fire resistance, sound absorption and structural stability. Behind the mass production of these high-performance panels lies a key piece of equipment: the rockwool sandwich panel machine. This advanced machinery integrates multiple technologies, including mechanical engineering, electrical control, hydraulic transmission and material science, to realize the automated and continuous production of rockwool sandwich panels. As the demand for energy-saving and environmentally friendly building materials continues to rise, the rockwool sandwich panel machine has gradually become an indispensable core equipment in the manufacturing chain, driving the transformation and upgrading of the industry towards high efficiency, precision and sustainability.

Working Principle of Rockwool Sandwich Panel Machine

The core working principle of the rockwool sandwich panel machine is to complete the integrated forming of the panel through a series of continuous and coordinated processes, from the uncoiling of the surface material to the compounding of the rockwool core and the final cutting and stacking. The entire production process can be divided into several key stages, each of which is closely linked and controlled by a unified system to ensure the stability and consistency of product quality.

First, the uncoiling and leveling stage. The surface materials of rockwool sandwich panels are usually pre-painted steel sheets or aluminum sheets, which are stored in the form of coils. The machine's uncoiling system uses hydraulic or electric drive to stably release the coiled material, and the leveling device corrects the deformation of the sheet caused by coiling, ensuring that the surface material is flat and smooth, laying the foundation for subsequent forming. During this stage, the tension of the uncoiling process is precisely controlled to avoid wrinkles or stretching of the sheet, which would affect the final product's appearance and structural strength.

Next is the forming stage of the surface material. The flattened surface material is fed into the roll forming system, which consists of a series of precision rollers with specific profiles. Under the action of the rollers, the surface material is gradually bent and formed into the required shape, such as corrugated or flat with edge locks. The roll forming process adopts progressive forming technology, which reduces the stress of the material during the forming process and ensures that the formed sheet has good dimensional accuracy and shape stability. The forming speed and pressure of the rollers can be adjusted according to the thickness and type of the surface material to adapt to different production requirements.

The third stage is the compounding of the rockwool core material. The rockwool core, which has been pre-processed into a specific thickness and width, is transported to the compounding zone through a dedicated conveying device. At the same time, the adhesive spraying system sprays a uniform layer of adhesive on the inner surface of the formed upper and lower surface materials. The adhesive is usually a polyurethane-based or epoxy-based adhesive with strong bonding strength and good aging resistance. After the rockwool core is placed between the upper and lower surface materials, the composite system applies uniform pressure to make the three layers closely bonded. Some advanced machines are also equipped with pre-heating and curing devices, which accelerate the curing speed of the adhesive through infrared heating or hot air circulation, ensuring that the composite panel has sufficient bonding strength in a short time.

The final stage is cutting and stacking. The continuously formed composite panel is transported to the cutting system, which adopts a non-stop cutting technology driven by servo motors. This technology allows the machine to cut the panel into the required length while maintaining continuous operation, greatly improving production efficiency. The cutting accuracy is controlled within a small range, ensuring that the length of each panel is consistent. After cutting, the finished panels are automatically transported to the stacking system, which arranges the panels neatly and stacks them to a specified height, facilitating subsequent packaging and transportation.

Structural Composition of Rockwool Sandwich Panel Machine

A complete rockwool sandwich panel machine is a complex system composed of multiple functional modules, each of which undertakes specific tasks and cooperates with each other to ensure the smooth progress of the entire production process. The main structural components include the uncoiling system, roll forming system, core material conveying and compounding system, adhesive spraying system, cutting system, stacking system and electrical control system.

The uncoiling system is usually composed of two or more uncoilers, which are used to uncoil the upper and lower surface materials respectively. Each uncoiler is equipped with a tension control device and a leveling mechanism. The tension control device uses frequency conversion technology to adjust the tension in real time according to the speed of the production line, ensuring the stable feeding of the coiled material. The leveling mechanism is composed of multiple leveling rollers, which can effectively eliminate the residual stress in the sheet and improve the flatness of the material. Some uncoilers are also equipped with edge alignment devices to prevent the deviation of the sheet during the uncoiling process.

The roll forming system is the core component of the rockwool sandwich panel machine, which determines the shape and dimensional accuracy of the surface material. It is composed of a frame, forming rollers, transmission mechanism and adjustment device. The frame is made of high-strength steel, which provides a stable support for the entire forming system. The forming rollers are made of high-quality alloy steel,to quenching and tempering treatment to improve their hardness and wear resistance. The surface of the rollers is precisely machined to ensure the profile accuracy. The transmission mechanism adopts a gearbox or chain drive to realize the synchronous rotation of multiple rollers. The adjustment device allows the operator to adjust the distance between the rollers according to the thickness of the material, ensuring the forming quality.

The core material conveying and compounding system includes a rockwool conveying device, a composite press and a curing device. The rockwool conveying device is usually a belt conveyor or a roller conveyor, which can adjust the conveying speed according to the production line speed to ensure the accurate matching of the core material and the surface material. The composite press adopts a double-belt pressing structure, which applies uniform pressure to the upper and lower surfaces of the composite panel through two endless belts. The pressure can be adjusted according to the type of adhesive and the thickness of the panel. The curing device is mainly used to accelerate the curing of the adhesive. Common curing methods include infrared heating, hot air heating and microwave heating. These methods can effectively improve the bonding strength and production efficiency of the panel.

The adhesive spraying system is composed of an adhesive storage tank, a metering pump, a spray gun and a pipeline. The adhesive storage tank is equipped with a heating and stirring device to keep the adhesive in a uniform state and prevent solidification. The metering pump accurately controls the amount of adhesive sprayed, ensuring that the adhesive layer is uniform and the bonding strength is stable. The spray gun is installed on a movable bracket, which can adjust the spraying width and angle according to the width of the panel. The pipeline is made of corrosion-resistant materials to prevent the adhesive from clogging the pipeline.

The cutting system is composed of a cutting tool, a servo drive mechanism and a length measuring device. The cutting tool is usually a circular saw blade or a hydraulic shear, which has high hardness and wear resistance. The servo drive mechanism ensures the high-speed and precise movement of the cutting tool, realizing non-stop cutting. The length measuring device uses an encoder to measure the length of the continuously moving composite panel in real time, and transmits the signal to the control system. When the panel reaches the set length, the control system issues a command to the cutting mechanism to complete the cutting action.

The stacking system includes a conveying roller table, a lifting platform and a positioning device. The finished panels are transported to the stacking area by the conveying roller table. The lifting platform can adjust the height according to the stacking height, ensuring that the panels are stacked neatly. The positioning device uses photoelectric sensors to align the edges of the panels, preventing deviation during stacking. Some advanced stacking systems are also equipped with automatic packaging devices, which can wrap the stacked panels with plastic film to protect them from moisture and damage during transportation.

The electrical control system is the "brain" of the rockwool sandwich panel machine, which is composed of a PLC controller, a touch screen, sensors and actuators. The PLC controller is responsible for processing the signals from various sensors and issuing control commands to the actuators. The touch screen provides a user-friendly man-machine interface, allowing the operator to set production parameters, monitor the operation status of the production line and troubleshoot faults. The sensors are installed in various parts of the machine to detect parameters such as the speed of the production line, the position of the material, the temperature of the curing device and the pressure of the composite press. The actuators include motors, hydraulic cylinders and solenoid valves, which execute the control commands issued by the PLC controller to realize the automatic operation of the machine.

Performance Characteristics of Rockwool Sandwich Panel Machine

With the continuous progress of technology, the rockwool sandwich panel machine has formed a series of outstanding performance characteristics, which have significantly improved the production efficiency, product quality and operational convenience of rockwool sandwich panels. The main performance characteristics are reflected in the following aspects:

High degree of automation. Modern rockwool sandwich panel machines adopt full computer integrated control technology, realizing the automatic linkage control of the entire production line from uncoiling, forming, compounding, cutting to stacking. The operator only needs to set the relevant parameters (such as panel thickness, length, production speed) on the touch screen, and the machine can complete the entire production process automatically. This not only reduces the labor intensity of the operator but also avoids the influence of human factors on product quality. Some advanced machines also have remote monitoring and control functions, allowing managers to monitor the operation status of the production line and adjust parameters in real time through a computer or mobile device, further improving the management efficiency of the production process.

High production efficiency. The continuous production mode of the rockwool sandwich panel machine greatly improves the production efficiency. The production speed can usually reach 3-8 meters per minute, and some high-performance machines can even reach 13-15 meters per minute when producing thin panels. Based on 250 working days a year and 10 working hours a day, the annual production capacity of a single production line can reach 800,000 to 1 million square meters. In addition, the non-stop cutting technology adopted by the machine ensures that the production line does not need to stop during the cutting process, further improving the continuous production capacity. The high production efficiency enables manufacturers to meet large-scale order requirements in a short time, enhancing their market competitiveness.

Excellent product quality. The rockwool sandwich panel machine adopts advanced precision manufacturing technology and strict quality control systems, ensuring that the produced panels have excellent dimensional accuracy and stable performance. The roll forming system with high precision ensures that the shape of the surface material is consistent and the dimensional error is small. The precise adhesive spraying system ensures that the adhesive layer is uniform, and the bonding strength between the surface material and the rockwool core is high, avoiding problems such as delamination. The non-stop cutting technology ensures that the length of the panel is accurate, and the cutting surface is flat and smooth. In addition, the machine is equipped with multiple quality detection devices, which can detect the thickness, flatness and bonding strength of the panel in real time. Once a quality problem is found, the machine will automatically alarm and stop, ensuring that unqualified products do not flow out of the production line.

Strong versatility and flexibility. The rockwool sandwich panel machine has strong versatility and can produce various types of rockwool sandwich panels by adjusting parameters and replacing some components. For example, by adjusting the thickness of the rockwool core and the type of surface material, panels with different thermal insulation performance and decorative effects can be produced. By replacing the roll forming rollers, panels with different shapes and sizes can be formed to meet the needs of different construction scenarios, such as roof panels, wall panels and cold storage panels. In addition, the modular design of the machine makes it easy to add or remove functional modules, further improving the flexibility of the production line. Manufacturers can adjust the configuration of the production line according to their own production needs and market changes, reducing the investment in equipment renewal.

Energy saving and environmental protection. With the increasing emphasis on environmental protection, modern rockwool sandwich panel machines have adopted a series of energy-saving and environmental protection technologies. In terms of energy consumption, the machine adopts a frequency conversion speed regulation system, which can adjust the speed of the motor according to the production load, reducing energy waste. The heating system adopts efficient heating elements, which have high thermal efficiency and low energy consumption. Some advanced machines also adopt a full closed-loop insulation design, which can reduce heat loss and further save energy. The energy consumption of these machines is usually 40% lower than that of traditional machines. In terms of environmental protection, the machine is equipped with a dust removal device to collect the dust generated during the production process, avoiding air pollution. The adhesive used in the production process is also environmentally friendly, which does not contain harmful substances and meets the national environmental protection standards.

Easy operation and maintenance. The rockwool sandwich panel machine is designed with a user-friendly man-machine interface, which is easy to operate. The touch screen displays the operation status of the production line and various parameters in real time, and the operator can complete the setting and adjustment of parameters with simple operations. In addition, the machine adopts a modular design, and each functional module is independent, which is convenient for maintenance and repair. The key components of the machine are made of high-quality materials, which have a long service life and low failure rate. The machine is also equipped with a complete maintenance manual and fault diagnosis system, which can help maintenance personnel quickly find and solve faults, reducing the downtime of the production line.

Application Scenarios of Rockwool Sandwich Panel Machine

The rockwool sandwich panel machine is widely used in the production of rockwool sandwich panels, which are widely used in various fields due to their excellent performance. Therefore, the application scenarios of the rockwool sandwich panel machine are closely related to the application fields of rockwool sandwich panels. The main application scenarios are as follows:

Construction industry. The construction industry is the largest application field of rockwool sandwich panels, and the rockwool sandwich panel machine plays an important role in it. Rockwool sandwich panels are widely used in the exterior walls, roofs and interior partitions of various buildings, such as residential buildings, commercial buildings, industrial workshops and public facilities. Due to their excellent thermal insulation performance, they can reduce the energy consumption of buildings and meet the requirements of energy-saving buildings. Their fire resistance and sound absorption performance can also improve the safety and comfort of buildings. For example, in the construction of industrial workshops, rockwool sandwich panels are used as wall and roof materials, which can not only insulate heat and sound but also have good structural strength, adapting to the harsh working environment of the workshop. In the construction of cold storage, rockwool sandwich panels with high thermal insulation performance are used to maintain the low temperature environment inside the cold storage, reducing the energy consumption of refrigeration equipment.

Industrial field. In the industrial field, rockwool sandwich panels are widely used in the insulation and fire protection of industrial equipment and pipelines. The rockwool sandwich panel machine produces panels with different thicknesses and sizes to meet the insulation needs of different equipment and pipelines. For example, in the power industry, rockwool sandwich panels are used to insulate boilers, pipelines and other equipment, reducing heat loss and improving energy utilization efficiency. In the chemical industry, rockwool sandwich panels are used as fireproof partitions and insulation materials for equipment, which can prevent the spread of fire and reduce the risk of accidents. In addition, rockwool sandwich panels are also used in the construction of industrial clean rooms, due to their good airtightness and cleanliness, which can meet the requirements of clean production.

Agricultural field. In the agricultural field, rockwool sandwich panels are widely used in the construction of greenhouses, livestock houses and other agricultural facilities. The rockwool sandwich panel machine produces panels with good thermal insulation performance, which can help greenhouses maintain a stable temperature environment, extending the growth cycle of crops. In the construction of livestock houses, rockwool sandwich panels can insulate heat and sound, improving the living environment of livestock and increasing the survival rate of livestock. In addition, rockwool sandwich panels are corrosion-resistant and moisture-resistant, which can adapt to the harsh environment in agricultural facilities and have a long service life.

Transportation field. In the transportation field, rockwool sandwich panels are used in the interior decoration and insulation of vehicles such as trains, ships and mobile homes. The rockwool sandwich panel machine produces lightweight and high-strength panels, which can reduce the weight of the vehicle while ensuring the insulation and fire protection performance. For example, in the interior decoration of trains and ships, rockwool sandwich panels are used as wall and ceiling materials, which have good fire resistance and sound absorption performance, improving the safety and comfort of passengers. In the construction of mobile homes, rockwool sandwich panels are used as the main building material, which can be quickly assembled and has good mobility, adapting to the needs of temporary housing.

Maintenance Strategies of Rockwool Sandwich Panel Machine

Proper maintenance is crucial to ensure the stable operation of the rockwool sandwich panel machine, extend its service life and improve production efficiency. The maintenance of the machine should follow the principles of prevention first and regular maintenance, and cover all aspects of the machine. The main maintenance strategies are as follows:

Daily maintenance. Daily maintenance is the basic work to ensure the normal operation of the machine, which should be completed by the operator before and after the operation of the machine. Before starting the machine, the operator should check the appearance of the machine for damage, check whether the connecting parts are loose, and check whether the lubricating oil, hydraulic oil and adhesive are sufficient. The operator should also check the electrical system, including the power supply, wires and sensors, to ensure that there is no damage or leakage. After starting the machine, the operator should observe the operation status of the machine, including the speed, noise and vibration, and check whether each functional module works normally. After the operation of the machine, the operator should clean the machine in time, remove the dust and residual adhesive on the surface of the machine and the components, and keep the machine clean. The operator should also record the operation status of the machine and the problems found during the operation in the maintenance log.

Regular maintenance. Regular maintenance is a systematic maintenance work carried out according to a certain cycle, which should be completed by professional maintenance personnel. The cycle of regular maintenance can be determined according to the operation time and working environment of the machine, usually divided into weekly, monthly, quarterly and annual maintenance. During regular maintenance, the maintenance personnel should comprehensively inspect and maintain the machine. For example, during weekly maintenance, the maintenance personnel should check the lubrication status of the machine, add lubricating oil to the moving parts, and check the wear status of the rollers and cutting tools. During monthly maintenance, the maintenance personnel should check the hydraulic system and pneumatic system, clean the filter, and check for oil leakage and air leakage. During quarterly maintenance, the maintenance personnel should disassemble and inspect the key components of the machine, such as the roll forming rollers, cutting tools and motors, and replace the worn parts. During annual maintenance, the maintenance personnel should comprehensively overhaul the entire machine, check the accuracy of the machine, and adjust and calibrate it.

Maintenance of key components. The key components of the rockwool sandwich panel machine, such as the roll forming rollers, cutting tools, servo motors and PLC controllers, have a crucial impact on the performance and service life of the machine. Therefore, special attention should be paid to their maintenance. For the roll forming rollers, the maintenance personnel should regularly check their surface for wear and deformation. If there is wear, they should be polished in time. If there is deformation, they should be replaced. The rollers should also be lubricated regularly to reduce wear. For the cutting tools, the maintenance personnel should regularly check their sharpness. If the tools are blunt, they should be sharpened or replaced. The cutting tools should also be cleaned regularly to remove the residual material on the surface. For the servo motors and PLC controllers, the maintenance personnel should keep them clean and dry, avoid moisture and dust, and check the wiring terminals for looseness. If there is a fault, the maintenance personnel should troubleshoot and repair it in time according to the fault diagnosis manual.

Fault handling. Despite regular maintenance, the rockwool sandwich panel machine may still have faults during operation. When a fault occurs, the operator should first stop the machine and cut off the power supply to avoid further damage to the machine. Then, the operator should record the phenomenon of the fault and report it to the maintenance personnel. The maintenance personnel should troubleshoot the fault according to the fault diagnosis system and maintenance manual. During the troubleshooting process, the maintenance personnel should follow the principle of from simple to complex, first checking the external components, such as the sensors and wires, and then checking the internal components, such as the motors and PLC controllers. After finding the cause of the fault, the maintenance personnel should repair or replace the faulty components in time. After the repair, the maintenance personnel should test the machine to ensure that it works normally. The maintenance personnel should also record the fault cause, repair process and replacement parts in the maintenance log for future reference.

Future Development Trends of Rockwool Sandwich Panel Machine

With the continuous development of the construction industry and the continuous progress of science and technology, the rockwool sandwich panel machine will face new development opportunities and challenges. In the future, the machine will develop in the direction of intelligence, high precision, high efficiency, energy saving and environmental protection. The main development trends are as follows:

Intelligent upgrading. Intelligence is the main development trend of the rockwool sandwich panel machine in the future. With the development of Industry 4.0, the machine will be equipped with more advanced sensors and intelligent control systems, realizing the intelligent perception, decision-making and control of the production process. For example, the machine will adopt machine vision technology to detect the surface quality and dimensional accuracy of the panel in real time, and use artificial intelligence algorithms to analyze the detection data, predict potential quality problems and adjust production parameters in advance. The machine will also realize the interconnection with other production equipment and the enterprise management system, forming an intelligent production line. Through the Internet of Things technology, the machine can transmit the operation data to the enterprise management platform in real time, facilitating managers to carry out production scheduling and quality management. In addition, the machine will also adopt collaborative robot technology to realize the automatic loading and unloading of materials and the automatic packaging of products, further improving the degree of automation of the production line.

Higher precision and efficiency. With the increasing demand for product quality, the rockwool sandwich panel machine will develop in the direction of higher precision. The roll forming system will adopt more advanced precision manufacturing technology, improving the dimensional accuracy of the formed sheet. The cutting system will adopt more precise servo drive technology, improving the cutting accuracy and speed. The adhesive spraying system will adopt more accurate metering technology, ensuring that the adhesive layer is more uniform. At the same time, the machine will also develop in the direction of higher efficiency. The production speed of the machine will be further improved, and the annual production capacity will be increased. The machine will also adopt a more efficient composite technology, reducing the curing time of the adhesive and further improving the production efficiency. In addition, the machine will adopt a more optimized production process, reducing the production cycle and improving the overall efficiency of the production line.

Green and low-carbon development. Under the background of global carbon neutrality, the rockwool sandwich panel machine will pay more attention to green and low-carbon development. The machine will adopt more advanced energy-saving technologies, such as solar energy and wind energy, to reduce the dependence on traditional energy sources. The heating system will adopt more efficient and low-carbon heating technologies, such as electromagnetic heating, which has high thermal efficiency and no pollution. The machine will also adopt more environmentally friendly materials and processes, reducing the generation of waste and emissions. For example, the machine will use water-based adhesives, which are more environmentally friendly than traditional solvent-based adhesives. The machine will also be equipped with more efficient dust removal and waste treatment devices, ensuring that the production process meets the highest environmental protection standards.

Modular and integrated design. The modular and integrated design of the rockwool sandwich panel machine will be further strengthened in the future. The machine will be composed of more standardized and universal modules, which can be quickly assembled and disassembled. Manufacturers can adjust the configuration of the production line according to their own production needs, reducing the time and cost of equipment installation and commissioning. The integrated design will integrate multiple functional modules into one, reducing the volume of the machine and saving the workshop space. In addition, the modular and integrated design will also facilitate the maintenance and repair of the machine, reducing the downtime of the production line. The machine will also adopt a more open design, which is convenient for the integration of new technologies and new functions, improving the scalability of the machine.

Conclusion

The rockwool sandwich panel machine is a key equipment in the production of rockwool sandwich panels, which has a crucial impact on the development of the construction and industrial material manufacturing industry. This article comprehensively explores the working principle, structural composition, performance characteristics, application scenarios, maintenance strategies and future development trends of the rockwool sandwich panel machine. It is found that the machine has the characteristics of high automation, high production efficiency, excellent product quality, strong versatility, energy saving and environmental protection, and easy operation and maintenance. It is widely used in the construction, industrial and agricultural fields. Proper maintenance can ensure the stable operation of the machine and extend its service life. In the future, the machine will develop in the direction of intelligence, high precision, high efficiency, energy saving and environmental protection.

With the continuous progress of technology and the increasing demand for energy-saving and environmentally friendly building materials, the rockwool sandwich panel machine will play a more important role in the industry. Manufacturers should pay attention to the development trends of the machine, continuously introduce advanced technologies and processes, and improve the performance and quality of the machine. Relevant practitioners should also strengthen their understanding of the machine, master its operation and maintenance skills, and promote the healthy and sustainable development of the rockwool sandwich panel industry.

《Rockwool Sandwich Panel Machine》Release Date: 2023/11/20

URL: https://www.sinowamachine.cn/en/tag/rockwool-sandwich-panel-machine.html

- PU Sandwich Panel Making Machine

- Rockwool Sandwich Panel Production Line

- PU Sandwich Panel Machine

- PU Sandwich Panel Production Line

- Mineral Wool Sandwich Panel Machine

- PUF Panel Machine

- Rock Wool Sandwich Panel Line

- Sandwich Panel Machines

- Sandwich Panel Lines

- Rockwool Sandwich Panel Machine

- Rockwool Sandwich Panel Line

- PU Sandwich Panel Line

- PU Panel Machine

- Foam Forming Machine

- Continuous Sandwich Panel Line

- Continuous PU Sandwich Panel Line

- PIR Sandwich Panel Line

- Polyurethane Sandwich Panel Line

- Automatic PU Sandwich Panel Production Line

- PU Foam Sandwich Panel Production Line