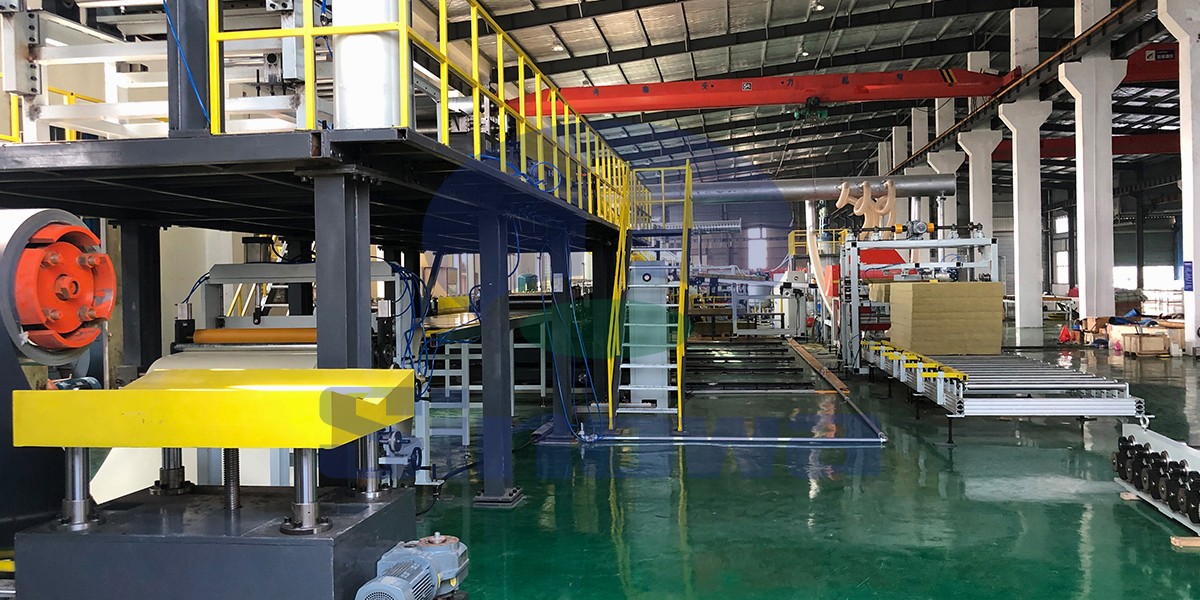

Sinowa is mineral wool sandwich panel production line manufacturer from china, dedicated to the research and development of high-end and high-efficiency, Sinowa is comprehensively taking the leading position in terms of efficiency, automation control level, HMI, environment protection and energy consumption, with subversive designs made in some critical technological fields to procure exceptional cost performance and customer-friendly experience for the entire mineral wool sandwich panel production line. The adoption of system integration technology and bus control technology accomplishes the full automatization of integrated and coordinated control of the entire mineral wool sandwich panel production line with accessible remote interactive communication. Ranking the first-class level in the world, it is currently the mineral wool sandwich panel production line in the market taking a comprehensive lead in high performance.

In the context of global emphasis on energy conservation, environmental protection and safe construction, mineral wool sandwich panels have emerged as a pivotal building material in industrial, commercial and residential sectors. Characterized by excellent fire resistance, thermal insulation, sound absorption and structural stability, these panels owe their consistent quality and large-scale application to the advanced mineral wool sandwich panel production line.

Mineral wool sandwich panels are composite structures composed of two outer metal facings and a mineral wool core. The mineral wool core, made from natural ores such as basalt or diabase melted at high temperatures and processed into fibers, is non-combustible and possesses low thermal conductivity. The outer metal facings, typically galvanized steel or aluminum sheets, provide structural strength and weather resistance. The production line integrates multiple technologies including mechanical processing, automatic control, chemical bonding and material forming, realizing the continuous and efficient manufacturing of sandwich panels with precise specifications and stable performance. Unlike traditional manual or semi-automatic production methods, modern production lines ensure the uniformity of panel thickness, bonding strength and surface flatness, laying a solid foundation for the wide application of mineral wool sandwich panels.

Core Components of Mineral Wool Sandwich Panel Production Line

A complete mineral wool sandwich panel production line is a systematic integration of multiple functional units, each playing a crucial role in the production process. These units are closely linked, forming a continuous production chain from raw material input to finished product output. The core components mainly include the uncoiling system, roll forming unit, mineral wool processing system, gluing system, laminating and pressing unit, cutting unit, and stacking and packaging system.

1. Uncoiling System

The uncoiling system is responsible for stably feeding the metal coil (the raw material of the outer facing) into the subsequent production process. It mainly consists of uncoilers, coil straighteners and automatic coil joining devices. The uncoilers adopt hydraulic mandrel structures, which can adapt to metal coils of different diameters and ensure smooth and stable uncoiling without causing deformation or damage to the metal sheets. The coil straighteners are equipped with multiple sets of leveling rollers to eliminate the internal stress of the metal coil and ensure the flatness of the metal sheet. The automatic coil joining device enables seamless connection between the end of the previous coil and the start of the next coil without stopping the production line, greatly improving production efficiency. This continuous feeding design ensures that the production line can operate continuously for a long time, reducing downtime losses and increasing annual output.

2. Roll Forming Unit

The roll forming unit is tasked with shaping the flat metal sheets into the required cross-sectional shape (such as trapezoidal, corrugated or ribbed) according to the design requirements of wall or roof panels. This unit is composed of multiple sets of sequential roll forming rollers, each of which gradually bends the metal sheet until the desired shape is achieved. The roll forming rollers are designed with high-precision machining technology to ensure the accuracy of the sheet shape and the consistency of the dimensions. Most modern roll forming units adopt a cassette-type design, which allows quick replacement of roller sets to produce panels of different shapes and specifications, enhancing the flexibility and adaptability of the production line. In addition, the unit is equipped with edging devices to trim the edges of the metal sheets, ensuring that the width of the sheets meets the standard requirements and avoiding burrs that may affect subsequent bonding.

3. Mineral Wool Processing System

The mineral wool processing system is the core part that determines the performance of the sandwich panel's insulation and fire resistance. It mainly includes mineral wool unwinding, cutting, trimming and conveying devices. The mineral wool, which is usually supplied in the form of large rolls or sheets, is first unwound and fed into the cutting device. The cutting device uses high-precision cutting tools to cut the mineral wool into strips or sheets of the required thickness and width according to the panel specifications. For roof panels, the mineral wool may need to be cut into trapezoidal shapes to fit the curved surface of the metal facing. The trimming device trims the edges of the cut mineral wool to ensure its size matches the metal facing and improve the airtightness of the final panel. To reduce dust pollution during processing, the system is usually equipped with dust removal devices, which not only protect the working environment but also prevent dust from affecting the bonding effect between mineral wool and metal sheets.

4. Gluing System

The gluing system is responsible for uniformly applying adhesive to the metal sheets to bond the metal facing and the mineral wool core firmly. The adhesive used is usually polyurethane (PU) glue, which has strong bonding strength, good weather resistance and compatibility with both metal and mineral wool materials. The gluing system consists of glue storage tanks, metering pumps, mixing heads and glue application nozzles. The metering pumps accurately control the amount of glue applied to ensure uniform glue coating and avoid excessive or insufficient glue that may affect the bonding strength or increase production costs. The glue application nozzles are designed to adapt to the shape of the metal facing, ensuring that the glue is evenly distributed even on curved or ribbed surfaces. Some advanced gluing systems also adopt automatic temperature control devices to adjust the viscosity of the glue according to the ambient temperature, ensuring stable bonding performance under different production conditions.

5. Laminating and Pressing Unit

The laminating and pressing unit is where the metal facings and the mineral wool core are combined into a single composite panel. This unit mainly includes a laminating conveyor and a double-belt pressing machine. First, the upper and lower metal sheets (after roll forming and gluing) and the processed mineral wool core are accurately positioned and laminated together on the conveyor. Then, the composite structure is fed into the double-belt pressing machine, which applies uniform pressure and temperature to ensure firm bonding between the layers. The double-belt pressing machine consists of two parallel steel belts, which are independently heated and insulated to maintain a stable temperature environment. The pressure and temperature can be adjusted according to the type of adhesive and the thickness of the panel, ensuring that the adhesive is fully cured and the panel achieves the required flatness and structural strength. The continuous pressing design ensures the consistency of the bonding quality of each part of the panel.

6. Cutting Unit

After the composite panel is formed, it needs to be cut into finished products of the required length. The cutting unit usually adopts a flying saw cutting device, which can cut the moving panel without stopping the production line, ensuring continuous production. The flying saw is equipped with a high-speed rotating saw blade and a precise positioning system, which can accurately cut the panel according to the preset length. The cutting accuracy can reach ±1mm, meeting the requirements of different construction scenarios. Some advanced cutting units also have a 180° rotating mechanism, which can cut panels in both directions, making it possible to produce short-length panels even at high production speeds. After cutting, the panel edges are trimmed to remove burrs and ensure the neatness of the finished product.

7. Stacking and Packaging System

The stacking and packaging system is the final link of the production line, responsible for sorting, stacking and packaging the finished panels. This system includes a conveying line, a stacking machine, a packaging machine and a control system. The finished panels are conveyed to the stacking machine by the conveying line, and the stacking machine stacks the panels neatly according to the preset quantity and specifications. The stacking process is controlled by a servo motor, ensuring stable and accurate stacking without damaging the panel surface. The packaging machine uses plastic film or waterproof paper to wrap the stacked panels, which can protect the panels from moisture, dust and collision during transportation and storage. Some packaging systems also have automatic weighing and labeling functions, which can print product information such as specifications, quantity and production date on the packaging, facilitating logistics management and quality tracking.

Working Principles and Production Processes

The mineral wool sandwich panel production line follows a continuous and automated production process, which can be divided into six main stages: raw material preparation, metal sheet processing, mineral wool processing, composite lamination, cutting and finished product packaging. Each stage is closely coordinated and controlled by a central control system to ensure the smooth operation of the entire production process.

First, in the raw material preparation stage, the metal coils (galvanized steel sheets, aluminum sheets, etc.) and mineral wool rolls are inspected and stored. The metal coils are checked for thickness, surface quality and corrosion resistance, while the mineral wool is inspected for density, thermal conductivity and fire resistance. Qualified raw materials are transported to the corresponding feeding positions of the production line, waiting for processing.

In the metal sheet processing stage, the metal coils are fed into the uncoiling system, where they are uncoiled and leveled to eliminate internal stress. Then, the flat metal sheets are sent to the roll forming unit, where they are gradually bent into the required shape by multiple sets of roll forming rollers. During the forming process, the edging device trims the edges of the metal sheets to ensure uniform width. After forming, the metal sheets are preheated by a preheating device to improve the bonding effect with the adhesive.

At the same time, in the mineral wool processing stage, the mineral wool rolls are unwound and fed into the cutting device. The cutting device cuts the mineral wool into strips or sheets of the required thickness and width according to the panel specifications. The trimmed mineral wool is conveyed to the laminating position through a special conveying line, and its position is adjusted to align with the metal sheets.

In the composite lamination stage, the gluing system applies adhesive uniformly to the inner surface of the formed metal sheets (upper and lower). Then, the upper metal sheet, mineral wool core and lower metal sheet are accurately laminated together on the laminating conveyor. The composite structure is then sent to the double-belt pressing machine, where it is pressed and heated under a certain pressure and temperature. The adhesive is fully cured under the action of heat and pressure, bonding the three layers firmly into a composite panel. The pressing temperature is usually between 80°C and 120°C, and the pressure is adjusted according to the thickness of the panel, generally between 0.3MPa and 0.8MPa.

In the cutting stage, the continuous composite panel coming out of the pressing machine is sent to the flying saw cutting unit. The control system calculates the cutting position according to the preset length, and the flying saw moves synchronously with the panel to complete the cutting. After cutting, the panel edges are trimmed to ensure neatness.

Finally, in the finished product packaging stage, the cut panels are conveyed to the stacking machine, which stacks them neatly. The stacked panels are then wrapped by the packaging machine and labeled with product information. The packaged finished products are transported to the warehouse for storage or directly delivered to customers.

Technological Characteristics of Modern Production Lines

With the continuous advancement of industrial automation and intelligent technology, modern mineral wool sandwich panel production lines have formed a series of distinctive technological characteristics, mainly reflected in high automation, high efficiency, flexibility and environmental protection.

1. High Automation

Modern production lines adopt a centralized control system based on digital servo technology and frequency conversion vector technology, realizing automatic linkage control of the entire production process from raw material feeding, roll forming, gluing, lamination, pressing to cutting, stacking and packaging. Operators only need to input production parameters (such as panel thickness, width, length, production speed, etc.) through the human-machine interface, and the system can automatically complete the entire production process. The control system can also real-time monitor the operation status of each unit, collect production data (such as output, qualified rate, material consumption, etc.), and realize remote monitoring and fault diagnosis. This high degree of automation not only reduces the dependence on manual operations but also improves the stability and consistency of product quality.

2. High Efficiency

The continuous production design of the production line greatly improves production efficiency. The production speed can be adjusted according to the product specifications and process requirements, generally ranging from 3m/min to 8m/min. Based on 250 working days per year and 10 working hours per day, the annual output of a single production line can reach 800,000 to 1 million square meters. The automatic coil joining device, flying saw cutting and other technologies ensure that the production line does not need to stop during the production process, reducing downtime losses. In addition, the optimization of the process flow (such as the integration of preheating and gluing, the synchronization of lamination and pressing) also shortens the production cycle and further improves production efficiency.

3. Flexibility

To meet the diverse needs of the construction market, modern production lines have strong flexibility and adaptability. Through the replacement of roll forming roller sets, the production line can produce wall panels and roof panels of different cross-sectional shapes (such as trapezoidal, corrugated, ribbed, etc.). By adjusting the cutting parameters and mineral wool processing specifications, panels of different thicknesses (50mm-200mm), widths (1000mm-1200mm) and lengths (2m-12m) can be produced. Some advanced production lines can even realize the combined production of mineral wool and polyurethane (PU) sandwich panels, further expanding the product range. This flexibility enables manufacturers to quickly respond to market changes and meet the personalized needs of different customers.

4. Environmental Protection

In response to the global call for environmental protection and energy conservation, modern production lines have adopted a series of environmental protection technologies and measures. In the mineral wool processing stage, dust removal devices are installed to collect the dust generated during cutting and trimming, reducing air pollution. The adhesive used in the gluing system is environmentally friendly and low-volatile, which meets the requirements of environmental protection standards. The double-belt pressing machine and other heating units adopt efficient insulation materials and energy-saving heating technology, reducing energy consumption. In addition, the production line can realize precise control of material consumption, reducing raw material waste. These environmental protection measures not only reduce the impact of production on the environment but also help manufacturers reduce production costs and improve market competitiveness.

Quality Control System in Production

The quality of mineral wool sandwich panels directly affects the safety and performance of buildings, so the production line must establish a strict quality control system to ensure that the finished products meet the required standards. The quality control of the production line runs through the entire production process, including raw material inspection, in-process quality control and finished product inspection.

1. Raw Material Inspection

Raw material inspection is the first line of defense for product quality. For metal coils, the inspection items include thickness, surface flatness, coating quality, corrosion resistance and mechanical properties. The thickness tolerance of the metal sheet should be within ±0.02mm, and the surface should be free of scratches, pits, rust and other defects. For mineral wool, the inspection items include density, thermal conductivity, fire resistance, fiber length and uniformity. The density of the mineral wool core should be between 100kg/m³ and 120kg/m³, the thermal conductivity should be less than 0.043W/(m·K), and it should be non-combustible. Only raw materials that pass the inspection can enter the production line.

2. In-Process Quality Control

In-process quality control is carried out in each production stage to timely find and correct quality problems. In the roll forming stage, the shape and size of the metal sheet are inspected in real-time using laser positioning technology to ensure that the dimensional error is within the allowable range. In the gluing stage, the amount and uniformity of glue application are monitored. The glue coating amount should be controlled at 150g/m²-200g/m², and there should be no missing coating or excessive coating. In the lamination and pressing stage, the pressure and temperature of the pressing machine are strictly controlled to ensure that the bonding strength between the metal sheet and the mineral wool core meets the requirements (the bonding strength should be greater than 0.15MPa). In the cutting stage, the length and edge flatness of the panel are inspected to ensure that the length error is within ±1mm.

3. Finished Product Inspection

Finished product inspection is the final quality check before the product leaves the factory. The inspection items include appearance quality, dimensional accuracy, bonding strength, thermal conductivity, fire resistance and sound insulation performance. The appearance of the finished panel should be neat, with no deformation, cracks, delamination or glue overflow. The dimensional accuracy should meet the design requirements. The bonding strength is tested by sampling, and the sample is subjected to a tensile test to ensure that it does not delaminate under the specified load. The thermal conductivity and sound insulation performance are tested in a professional laboratory to ensure that they meet the relevant standards. Only finished products that pass all inspection items can be packaged and delivered.

Application Fields and Market Trends of Mineral Wool Sandwich Panels

The excellent performance of mineral wool sandwich panels has made them widely used in various fields, and the continuous improvement of production line technology has further promoted the expansion of their application fields. At the same time, driven by policies such as energy conservation and environmental protection and the development of prefabricated construction, the market demand for mineral wool sandwich panels is showing a growing trend, which in turn promotes the continuous upgrading of production line technology.

1. Application Fields

Mineral wool sandwich panels are mainly used in industrial buildings, commercial buildings, residential buildings and other fields. In industrial buildings (such as factories, warehouses, logistics centers), they are used as external walls, roofs and internal partitions, taking advantage of their excellent fire resistance, thermal insulation and sound insulation performance to create a safe and comfortable working environment. In commercial buildings (such as shopping malls, office buildings, stadiums), they are used as exterior wall cladding and interior decoration materials, which not only meet the requirements of energy conservation and fire safety but also have a beautiful appearance. In residential buildings, they are used in prefabricated houses, partition walls and roof insulation, which can shorten the construction period and improve the energy efficiency of the building. In addition, they are also used in special buildings such as power plants, food processing plants and agricultural greenhouses, showing a wide range of application prospects.

2. Market Trends

With the global construction industry's increasing emphasis on energy conservation, environmental protection and fire safety, the market demand for mineral wool sandwich panels is continuously growing. Especially in the field of prefabricated construction, due to the advantages of mineral wool sandwich panels such as light weight, easy installation and short construction period, their application proportion is increasing year by year. At the same time, the renovation of existing buildings also provides a huge market space for mineral wool sandwich panels, as they can be seamlessly integrated into renovation projects to improve the energy efficiency and fire safety of buildings.

In terms of technology development, the future mineral wool sandwich panel production line will tend to be more intelligent, green and high-precision. The application of artificial intelligence technology will realize the intelligent optimization of production parameters and the predictive maintenance of equipment; the adoption of more environmentally friendly materials and energy-saving technologies will further reduce the environmental impact of production; the improvement of machining accuracy will make the product dimensional tolerance more precise and the performance more stable. In addition, the integration of digital technology and production lines will realize the whole-process traceability of products, further improving the level of quality management.

Conclusion

The mineral wool sandwich panel production line is a key equipment in the modern construction material industry, which integrates multiple technologies such as mechanical engineering, automatic control, chemical engineering and materials science. Its core components work together to realize the continuous and efficient production of mineral wool sandwich panels with excellent performance. The high automation, high efficiency, flexibility and environmental protection of modern production lines not only improve production efficiency and product quality but also promote the sustainable development of the construction material industry.

With the continuous advancement of technology and the continuous expansion of market demand, the mineral wool sandwich panel production line will continue to undergo technological innovation and upgrading. In the future, it will play a more important role in promoting the transformation and upgrading of the construction industry, realizing energy conservation and emission reduction, and ensuring building safety. For manufacturers, continuously improving the technological level of production lines, optimizing the production process and strengthening quality control are the key to enhancing market competitiveness. For the construction industry, the wide application of high-quality mineral wool sandwich panels produced by advanced production lines will help build a more energy-saving, environmentally friendly and safe built environment, promoting the healthy and sustainable development of the global construction industry.

《Mineral Wool Sandwich Panel Production Line》Release Date: 2023/11/20

URL: https://www.sinowamachine.cn/en/tag/mineral-wool-sandwich-panel-production-line.html

- PU Sandwich Panel Making Machine

- Rockwool Sandwich Panel Production Line

- PU Sandwich Panel Machine

- PU Sandwich Panel Production Line

- Mineral Wool Sandwich Panel Machine

- PUF Panel Machine

- Rock Wool Sandwich Panel Line

- Sandwich Panel Machines

- Sandwich Panel Lines

- Rockwool Sandwich Panel Machine

- Rockwool Sandwich Panel Line

- PU Sandwich Panel Line

- PU Panel Machine

- Foam Forming Machine

- Continuous Sandwich Panel Line

- Continuous PU Sandwich Panel Line

- PIR Sandwich Panel Line

- Polyurethane Sandwich Panel Line

- Automatic PU Sandwich Panel Production Line

- PU Foam Sandwich Panel Production Line